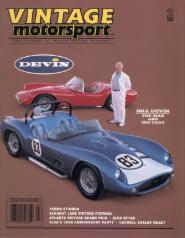

The Bill Devin Story

With the McAfee fiasco behind him, Devin decided in 1954 that he could build cars just as well as anybody else, especially the Europeans. Bill says he cleaned out a chicken house and got it ready to make what soon would be called Devin-Panhards. Fiberglass construction was just becoming known in the early Fifties, but Devin quickly learned about the new art by building fiberglass bodies for the Panhards. It was the first Devin fiberglass body.

Another milestone in Devin's career was the first use of a belt driven OHC engine. But, typical of Bill's disdain for paperwork and the bureaucracy, he never patented his idea which has since been used by every auto manufacturer.

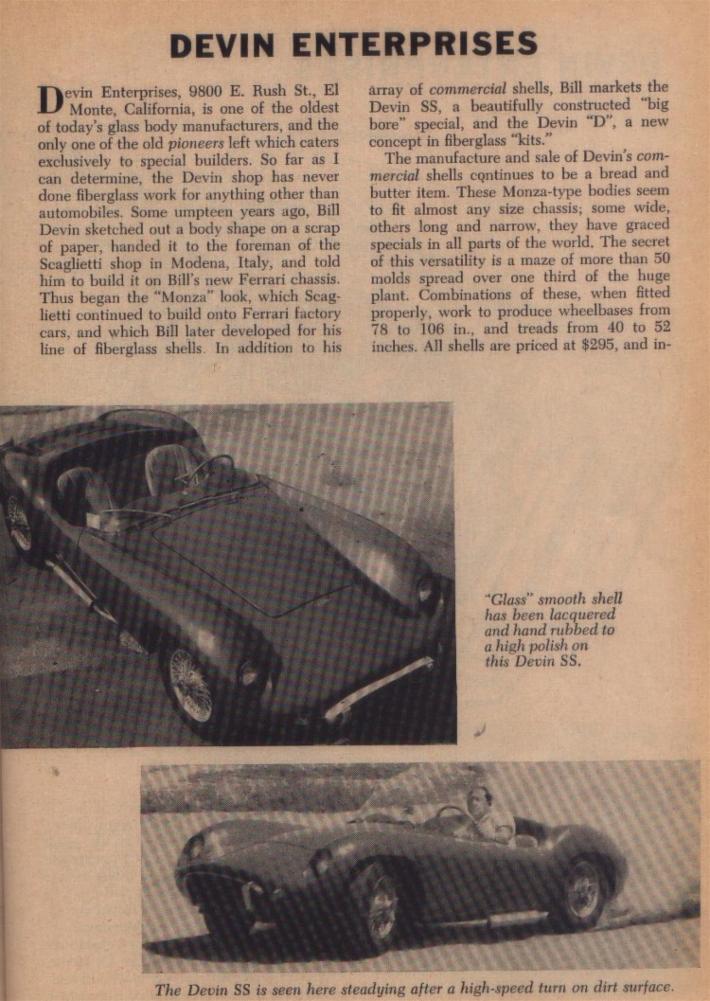

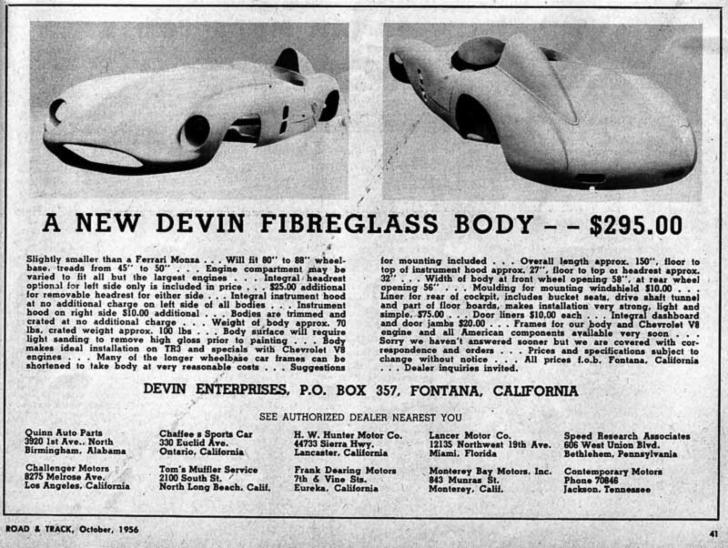

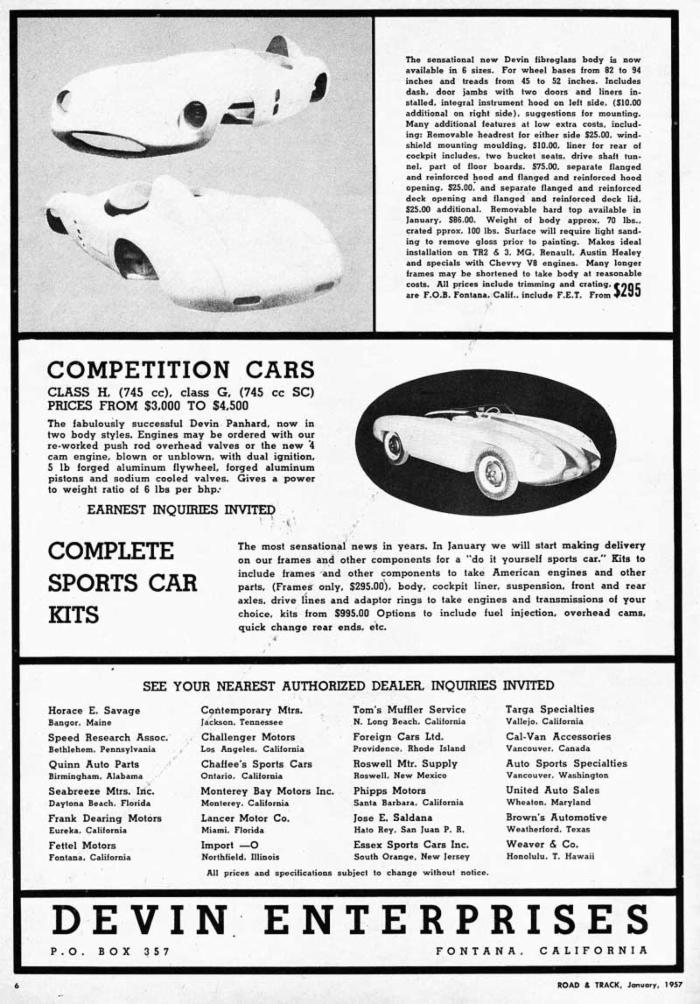

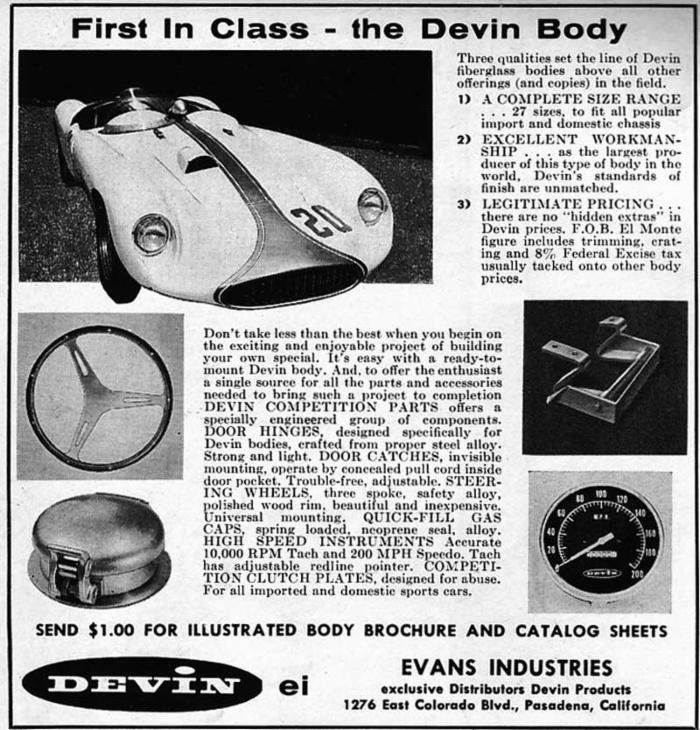

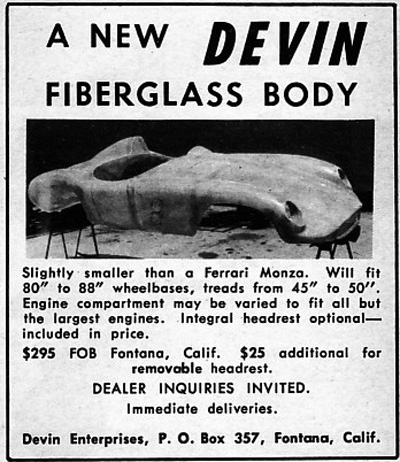

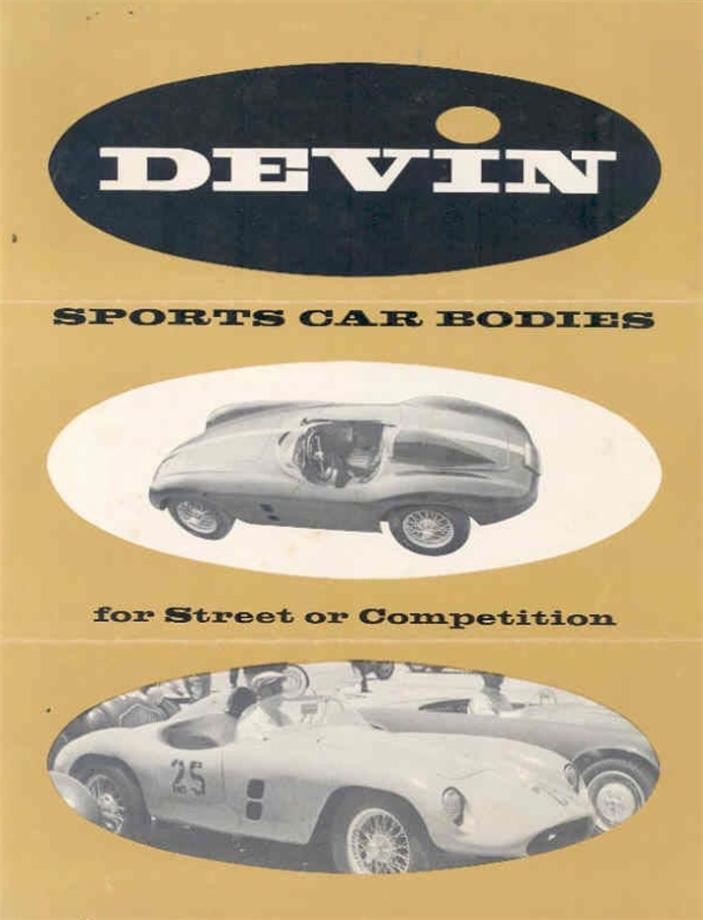

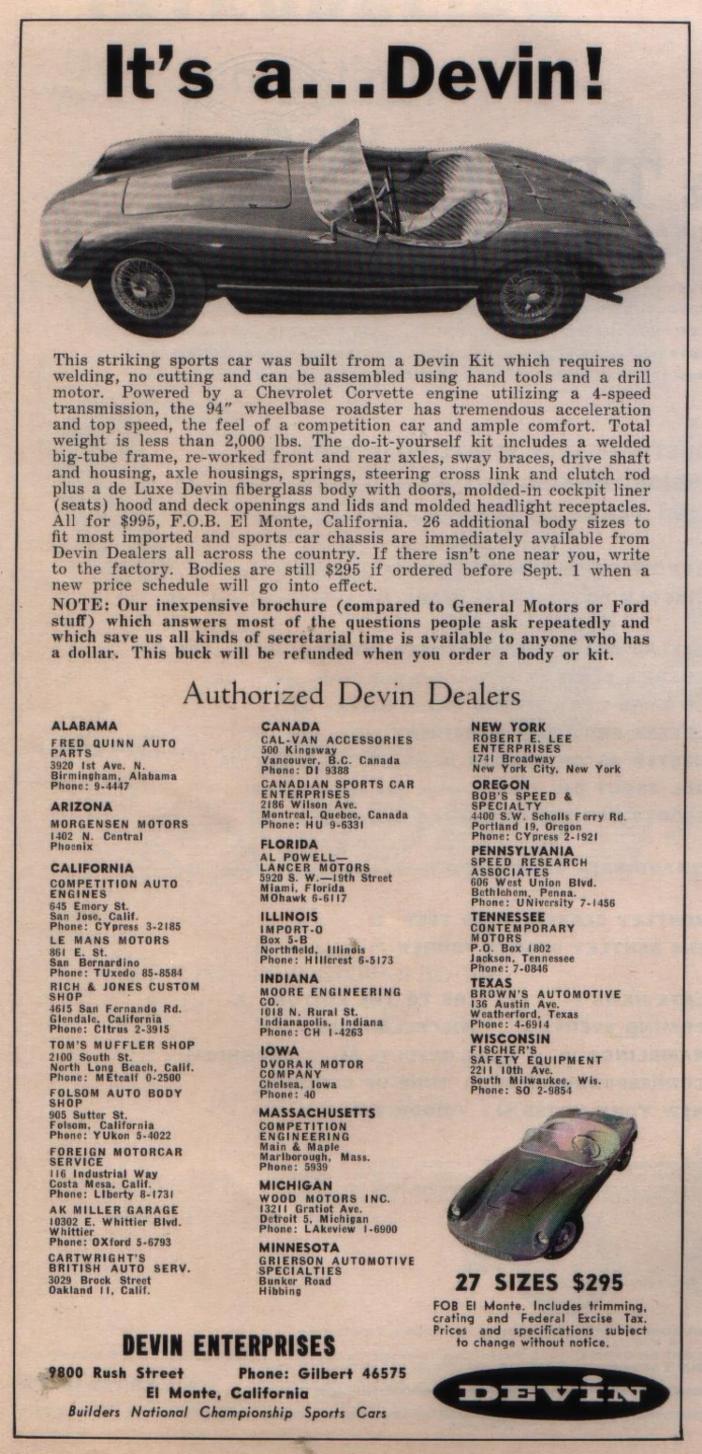

The next chapter in Bill Devin's life is perhaps the one for which he is best known - the attractive, Ferrari Monza-like Devin bodies which were ultimately available in 27 variations to fit cars ranging from a tiny Crosley Hot Shot to a TR3 to a hefty Allard. Devin was easily the largest producer of fiberglass bodies in the late Fifties and early Sixties in a very competitive business. He had dealers in 50 states and shipped bodies to nearly all the countries of Europe, all through Central and South America and even South Africa.

Devin-bodied Triumph

It offered Ferrari Monza looks for $295.

How many of these names do you remember? Byers, Almquist, Alken, La Dawri, Microbond, Fibrefab, Atlas, Kellison, Allied, Conquest, Victress and Microplas. These were some of Devin's competitors and contemporaries and most have been forgotten in time, but the name Devin still features prominently as Devin held his own with the right mix of low cost and quality plus the amazing range of sizes. Devin bodies were always praised for being so smooth that they didn't even look like fiberglass and the finish work was almost always superior to his competitors.

Contrary to what many have said, Bill Devin did not set out to build a Corvette beater or for that matter a racer when he began to build the SS in 1957. In his words, "I wanted to build the best sports car in the world." Some say he succeeded even though he had no sales organization or financing.

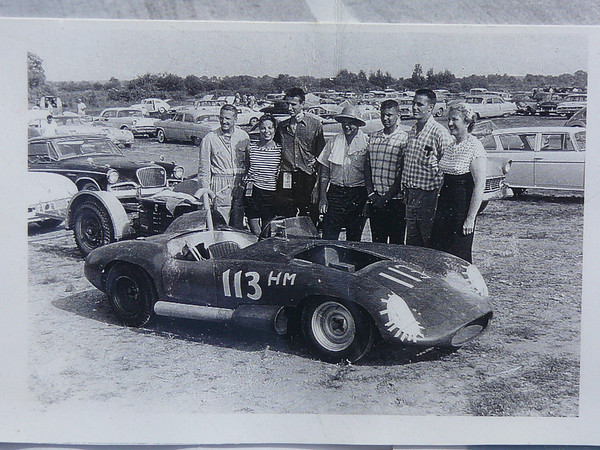

Art Evans and his father and Ocee Ritch were the sole distributors for the SS and their sales manager, Pete Woods, raced the SS to provide media exposure to attract sales. In 1959, Woods proved the SS a rapid, reliable sports car by winning the Cal Club C-Modified championship. Perhaps the Automobile Manufacturer's Association ban on racing and the consequent de-emphasis on high performance and horsepower did the SS in, as Devin futilely tried to find financial backing to build 100 examples of the car to homologate it for racing. One thing was for sure - the SS could show its heels to competitors that cost twice as much, and it was beautiful!

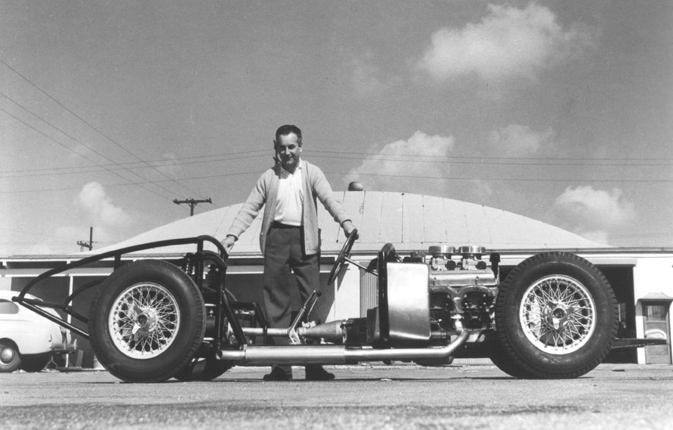

Malcolm MacGregor was a textile engineer who worked for Noel Hillis, a former Norton motorcycle racer who occasionally raced F1 cars at the amateur level. Hillis owned a hemstitching company called Devonshire Engineering, and both were sports car enthusiasts. MacGregor, tired of the hapless chassis of his MG TC, had designed a replacement chassis with a Jaguar XK engine. It was the desire to find a lightweight body that led them to Devin. This was in early 1957.

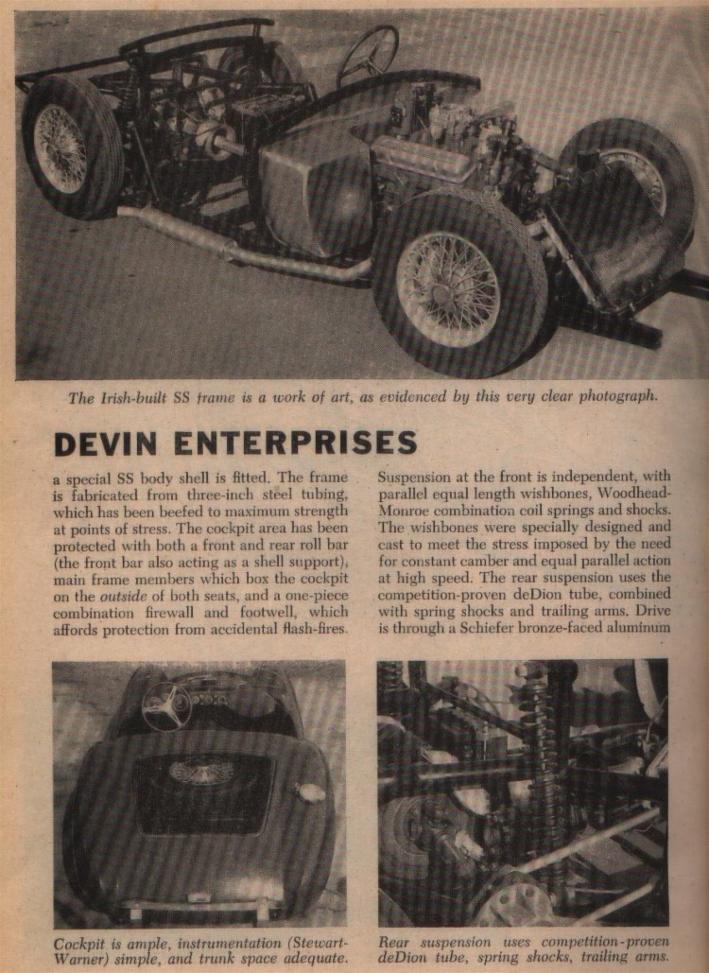

Instead of selling them a body, Devin made arrangements to have them make a chassis for him to his design. Devin's design had the driver and passenger sitting down in a perimeter frame instead of on top of it as MacGregor's frame did, and as Corvettes, Ferraris and all other cars of the era did. Devin wanted the frame 94" wheelbase instead of 90" W.B. as MacGregors was. They finally compromised at 92" W.B.

Devin's frames were made of 3" tube instead of the 4" that MacGregor used on the prototype. The generator and battery were moved behind the driver and passenger to transfer some weight. The car weight on the street was 45% front and 55% rear. The fuel tanks were molded in the two rear fenders.

Several reasons why the cars were made in Belfast have been written up; none of which are true. The reason they were made in Belfast was because Belfast is in North Ireland, which is part of England (or the British Isles if you prefer) and there was availability for disc brakes, rack and pinion steering, coil over shocks, knock-off wire wheels, racing tires, wood rim steering wheels, large quick-fill gas caps, etc. None of these things were available in the U.S. at that time.